Solar collectors are assembled using selected materials and advanced techniques, which result in highly efficient, durable products you can rely on for years. Solar collectors are assembled using selected materials and advanced techniques, which result in highly efficient, durable products you can rely on for years.

The products are environmentally friendly, remarkably versatile and offer high performance even in extreme environments. The wide range of solar collectors provide cost- effective solutions which comply with a varied of international standards and fulfill different requirements.

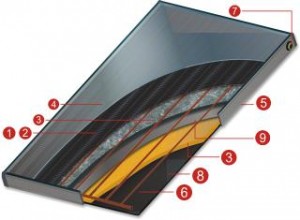

1. Absorber plate

Consists of welded copper bend ultrasonically welded to copper risers, providing excellent heat transfer between the fins and risers, ensuring high efficiency. Inexpensive yet durable aluminum absorber plate is available.

2. Absorber plate Coating

Coated wither with a sputtering coating or with black chrome on nickel or with highly distinctive black solar paint. All allow excellent energy absorption even in cooler climates.

3. Heat insulation

The absorber plate is encased in a 30 mm rigid polyurethane foam, with an option to additional layer of glass wool, retaining the collector’s heat.

4. Solar Glass Glazing

The single panel 3.2 mm solar glass is patterned to reduce reflection and tempered to maximize strength and durability. The low iron oxide content of 0.03% enables a high solar transmittance of 91%.

5. Casing

All anodized aluminum extrusion casings are made of solid construction available in a natural or black or red color. Galvanized steel casings are available in black, grey or white polyester finishing.

6. Tubing grid

5/8″ or 8 mm copper risers brazed to 1 1/8″ or 7/8″ copper manifolds with optimal flow distribution.

7. Piping connection

Four 3/4″ BSP female brass adaptors, flare for quick fittings or clear cut edge for connector brazing.

8. Base plate

Made in black polypropylene.

|